|

Atlas YM-34 Review

I had seen

the Atlas car in one of Car Action's touring car

special issues. It looked totally awesome! Anyway,

I had thought about buying one, but the cost seemed

prohibitive. In November, Integy, the importer,

dropped the car's price almost $50, and I was

sold.

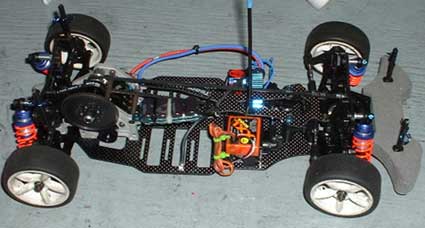

This

is how the car comes out of the box, minus electronics.

Note graphite parts, threaded shocks, metal bulkhead/motor

mount. Pretty good for a $200 kit. This

is how the car comes out of the box, minus electronics.

Note graphite parts, threaded shocks, metal bulkhead/motor

mount. Pretty good for a $200 kit.

Build

Up

When the car arrived,

I put it together in about 7-8 hours. The parts

quality was excellent, which reassured me since

the car was an unknown to me. In fact, the only

flaw that really stuck out was the fact that the

countersinking was not that great. Some of the plastic

was a little more flexible than I would have liked,

but they do offer graphite versions of most of the

parts.

The metal parts were flawless, however. Having the

motor mount and side plate included in the kit was

excellent considering the price, especially since

threaded shocks and all the woven graphite are also

included too.Another nice part was that the car

was not overly sloppy. While there was some tolerance,

it wasn't as bad as some cars that I have put together.

Not a pivot ball car, but good.

Assembly was ok despite the horrendous translation

from Japanese, ("foolishness prevention"?). What

saved the manual had to be the excellent drawings

and parts diagrams. I didn't have much trouble figuring

what was what. Someone not familiar with r/c would

definitely have a hard time, though.

The diffs are of the Associated/HPI style. Once

assembled, they were pretty smooth. I do recommend

getting some HPI 2.4 mm diff nuts, as there is a

part on the tree which uses those nuts instead of

just threading the screw into a plastic nut. Delrin

halves are also available for even more drive train

lightening. The car accelerates well with steel

halves, so I can't imagine how rocket like it would

be with the plastic halves.

As I mentioned before, I countersunk the chassis,

and also beveled the battery slots. For 2400s and

3000s you may need to lengthen the slots as well.

Tape is the recommended battery securing system,

and while the tape slots are wide and easy to deal

with, Schumacher battery hold downs are rumored

to fit nicely on the chassis. Tape is sort of lame,

so I intend on trying the Schumacher stuff.

Once the chassis is together, the flex probably

less than a Pro2, but there is still flex evident.

The metal bulkhead cuts down on the flexing. I always

felt that the HPI, or any 2 deck car needed a metal

bulkhead, and this car is that much ahead of the

game. What is also nice is that the bulkheads are

not part of the suspension mounts, so there is quite

a bit of adjustability that I'll get into later.

Another really great feature of the kit is that

threaded shocks are stock. The shocks also can be

built with a bladder, and filled from the top, or

filled from the bottom Losi style. I have found

so far that the Losi style bottom fill is the easiest

to get the shocks consistent. Otherwise they are

very smooth, and the threaded collars adjust easily.

The shock towers are also interesting in that they

are slightly thicker than the chassis plate. This

helps to cut down on flex. The only problem is that

the kit plastic is flexible, and the diff housings,

which the towers bolt to, allow the towers to move

too much to be effective. Both graphite plastic

and aluminum diff housings are available. Still,

a better quality plastic would help quite a bit.

The rest of the parts are excellent quality. Steel

turnbuckles, steel CVD type drive shafts, rubber

sealed ball bearings, they all add up to great value.

Like I said the only gripe is the plastic composition.

The amount of adjustment on this car really sets

it apart from the rest of the cars that it is often

mistaken for. "It looks like an HPI". HPIs don't

allow you to change the rear roll center and kick

up out of the box, nor do they have more than 2

choices for the inboard camber link position. The

front also has the same features. Really, the car

it is more comparable to would be an Xpress. This

is a racecar more than a beginner's car.

Performance

Once built, I took off

for S&N's Trackside Raceway in Milwaukee, WI. I

had set the car up to the spec's from the setup

sheet from Integy's website. The only changes I

made from their setup was to run 10wt lighter oil

in the rear, 7* of caster in the front, and to make

the rear camber link as long as possible.

As soon as I threw the car on the track, it felt

great. I was surprised at how quick it was as well.

The car had very good acceleration out of the corner.

I ran in the pro stock class for the night.

After the two qualifiers, I was 5th in the A. Not

bad, but the car didn't turn in as hard as I would

have liked. In retrospect, 9* of caster would have

been better. After having had the car for a little

while now, I see it needs more caster to turn in

from high speed.

In the main, I had a very good run. I came from

the back of the field to the fight for 2nd, 3rd,

and 4th. After a few laps, I had the 2nd place car

in my sights. I definitely was faster than him,

but a "racing incident" put me back to 6th. With

only about 45 seconds left, the only thing I could

do was to catch the 5th place car and pass him.

The other cars were too far gone.

I again raced the car at S&N's on New Years' Day.

This time the race was not as successful. I managed

to dial myself out early in the day. Basically,

I lowered the front roll center too much, resulting

in the car looking like a big Caddy out on the track.

I tried to use stiffer springs and oil, but the

car was only marginally better. As I found out later,

the difference of the roll center's height from

the center of gravity's height caused the car to

sway like a pendulum. My results that day weren't

too good, although I did manage to come from last

starting position in my stock race to 2nd.

My latest testing seems to show the rear suspension

mounts should be 2 to 4mm high, and the front 1.5

to 2.5mm. The front should generally be lower than

the rear. That way the rear roll center is higher

than the front roll center. I also run a minimum

of 1mm kick up in the rear, and 0 to 1mm in the

front. Your mileage may vary, however. This seems

to be what works for carpet. I also recommend sway

bars for the car.

Overall, I felt the car was excellent the first

time I ever raced it. It was one of the faster cars

on the track! With a little more dialing in time,

I think it will be able to run with and from any

of the top cars out there.

|